Click on a picture to view a larger version.

|

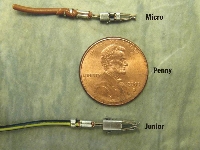

Shown here are the most common of the terminal ends you'll find in a VW/Audi. They are made by Tyco Electronics. The one above the penny is of the "micro" size, and the one below the penny is of the "junior" size. They are the female, also called "timers" where as the males are called "tabs". |

|

Here is a very typical terminal housing used in a VW. For those with the 1.8T engine, this is the one used on the coils and houses the junior size terminals (timers). |

Why should you send a postcard? Because it is cheap to do and as we all know, the US Post Office is funding it's Super Mutant Army Project with fees from postcards stamps. I would really like to see a Super Mutant Army deliver my mail in the near future.

Thank you.